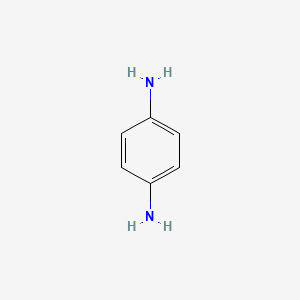

As a supplier of P-Phenylenediamine, I understand the critical role it plays in various industries, from the production of dyes and pigments to rubber chemicals and pharmaceuticals. In recent years, the demand for P-Phenylenediamine has been on the rise, and with that comes the need to improve production efficiency. In this blog post, I will share some strategies and insights that can help enhance the production efficiency of P-Phenylenediamine.

1. Optimize the Raw Material Supply Chain

The quality and availability of raw materials are fundamental to the efficient production of P-Phenylenediamine. We need to establish strong partnerships with reliable suppliers to ensure a stable supply of key raw materials. Conducting regular quality checks on incoming raw materials can minimize the risk of production disruptions caused by sub - standard inputs.

Moreover, analyzing the market trends of raw materials can help us make informed decisions on purchasing. For example, if the price of a certain raw material is expected to rise in the near future, we can consider increasing our inventory within a reasonable range. This not only secures the supply but also potentially reduces the cost in the long run.

2. Upgrade Production Equipment

Outdated production equipment can significantly limit production efficiency. Investing in modern and advanced equipment can lead to substantial improvements. For instance, new reaction vessels with better heat transfer capabilities can speed up the reaction process, reducing the production cycle time.

Automated control systems can also be introduced to monitor and adjust the production parameters in real - time. These systems can ensure that the reaction conditions, such as temperature, pressure, and reaction time, are precisely maintained, resulting in higher product quality and yield. Additionally, automated equipment can reduce human errors and labor costs.

3. Improve Process Technology

Continuous research and development of process technology are essential for enhancing production efficiency. We can collaborate with research institutions or universities to explore new synthesis methods for P - Phenylenediamine. Newer methods may offer advantages such as higher selectivity, fewer side - reactions, and lower energy consumption.

For example, some novel catalytic processes can improve the reaction rate and conversion rate of the raw materials. By optimizing the reaction conditions and catalysts, we can achieve a more efficient production process. Regularly reviewing and updating the production process based on the latest research findings can keep our production at a competitive level.

4. Enhance Employee Training

Well - trained employees are a valuable asset in the production process. Providing comprehensive training programs can improve the skills and knowledge of our workforce. Employees should be trained not only on the operation of production equipment but also on safety procedures and quality control.

Regular training sessions can keep employees updated on the latest production techniques and industry standards. Encouraging employees to participate in professional development courses and workshops can also stimulate innovation and problem - solving capabilities within the team. A highly skilled workforce can operate the production equipment more efficiently, troubleshoot problems more quickly, and contribute to continuous improvement in the production process.

5. Implement Quality Control Systems

Effective quality control systems are crucial for ensuring the efficiency of P - Phenylenediamine production. By implementing strict quality control measures at every stage of the production process, we can identify and correct any quality issues promptly.

This includes in - process inspections, where samples are taken at various points during production to check for key quality indicators. Final product inspections are also essential to ensure that the P - Phenylenediamine meets the required standards. By preventing defective products from entering the market, we can reduce waste and rework, thereby improving overall production efficiency.

6. Energy Management

Energy consumption is a significant cost factor in the production of P - Phenylenediamine. Implementing energy - saving measures can not only reduce costs but also contribute to environmental sustainability.

We can conduct energy audits to identify areas where energy is being wasted. For example, optimizing the heating and cooling systems in the production facility can reduce energy consumption. Using energy - efficient equipment and technologies, such as high - efficiency motors and LED lighting, can also make a significant difference. Additionally, exploring renewable energy sources, such as solar or wind power, can further reduce our reliance on traditional energy sources.

7. Supply Chain Integration

Integrating our supply chain can lead to better coordination and efficiency. By sharing information with our suppliers and customers, we can better manage inventory levels, production schedules, and delivery times.

For example, implementing a just - in - time (JIT) inventory system can reduce inventory holding costs while ensuring that raw materials are available when needed. Collaborating closely with customers to understand their demand patterns can also help us plan our production more effectively.

Product - Related Links

In addition to P - Phenylenediamine, we also offer other high - quality pharmaceutical intermediates. You can find more information about 2-Acetylthiophene, Bromofluorobenzene Synthesis, and Thermal Stability Silicone Fluid on our website.

Conclusion

Improving the production efficiency of P - Phenylenediamine requires a comprehensive approach that encompasses raw material management, equipment upgrade, process technology improvement, employee training, quality control, energy management, and supply chain integration. By implementing these strategies, we can not only increase our production capacity and reduce costs but also enhance the quality of our products.

If you are interested in our P - Phenylenediamine products or other pharmaceutical intermediates, please feel free to contact us for further discussions and procurement negotiations. We are committed to providing high - quality products and excellent service to meet your needs.

References

- Smith, J. (2018). Chemical Production Efficiency: Strategies and Case Studies. Chemical Industry Press.

- Johnson, M. (2019). Advances in Process Technology for Chemical Synthesis. Journal of Chemical Engineering, 25(3), 123 - 135.

- Brown, A. (2020). Energy Management in the Chemical Industry. Sustainable Energy Journal, 18(2), 89 - 98.